Understanding Medjool Bags: Essential Insights for Professionals in the Plastic Industry

In the realm of plastic products, understanding the utility and characteristics of different types of bags is paramount, especially when considering specialized options like Medjool bags. These bags, typically used for packaging and storing premium Medjool dates, have gained attention due to their unique properties and the advantages they offer in the food and chemical sectors.

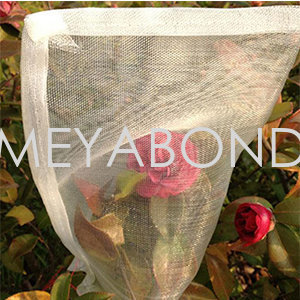

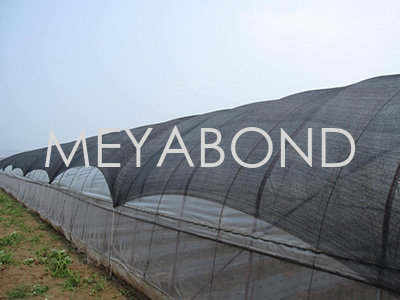

Medjool bags are designed to be both robust and versatile, making them suitable for a variety of applications beyond just fruit packaging. Their construction often involves high-quality plastic materials, ensuring durability and protection against environmental factors. This is particularly important in the chemical industry, where products need to be safeguarded against moisture, contamination, and physical damage.

One of the key benefits of Medjool bags is their ability to maintain the freshness of perishable goods. The design and material composition allow for breathability while creating a barrier against external contaminants. This is crucial for industries dealing with sensitive products, where spoilage can lead to significant financial losses and compromise product integrity.

Additionally, the flexibility of Medjool bags means they can be adapted in size and thickness to meet specific packaging requirements. Whether you are looking to package small quantities for retail or bulk for wholesale distribution, these bags can be tailored to fit your needs. This adaptability not only enhances efficiency in packaging operations but also aids in inventory management by allowing for a range of product sizes.

Furthermore, sustainability has become a pressing concern across the plastic industry. As more companies are looking to reduce their environmental footprint, understanding the materials used in Medjool bags can help in making informed decisions. Many manufacturers are exploring biodegradable options or recyclable materials, which can align with corporate responsibility goals and appeal to eco-conscious consumers.

When sourcing Medjool bags, it’s essential to consider the production standards and certifications of the manufacturers. Working with suppliers who adhere to strict quality control measures ensures that the bags meet safety and regulatory requirements, particularly when they are intended for food or chemical products.

In conclusion, Medjool bags are more than just packaging solutions; they are integral components that can enhance product safety, shelf life, and brand reputation in the competitive plastic industry. By understanding their unique properties and applications, professionals can make more informed choices that align with both operational needs and sustainability goals. Adapting these insights into your packaging strategy can lead to improved efficiency and customer satisfaction in your operations.

Medjool bags are designed to be both robust and versatile, making them suitable for a variety of applications beyond just fruit packaging. Their construction often involves high-quality plastic materials, ensuring durability and protection against environmental factors. This is particularly important in the chemical industry, where products need to be safeguarded against moisture, contamination, and physical damage.

One of the key benefits of Medjool bags is their ability to maintain the freshness of perishable goods. The design and material composition allow for breathability while creating a barrier against external contaminants. This is crucial for industries dealing with sensitive products, where spoilage can lead to significant financial losses and compromise product integrity.

Additionally, the flexibility of Medjool bags means they can be adapted in size and thickness to meet specific packaging requirements. Whether you are looking to package small quantities for retail or bulk for wholesale distribution, these bags can be tailored to fit your needs. This adaptability not only enhances efficiency in packaging operations but also aids in inventory management by allowing for a range of product sizes.

Furthermore, sustainability has become a pressing concern across the plastic industry. As more companies are looking to reduce their environmental footprint, understanding the materials used in Medjool bags can help in making informed decisions. Many manufacturers are exploring biodegradable options or recyclable materials, which can align with corporate responsibility goals and appeal to eco-conscious consumers.

When sourcing Medjool bags, it’s essential to consider the production standards and certifications of the manufacturers. Working with suppliers who adhere to strict quality control measures ensures that the bags meet safety and regulatory requirements, particularly when they are intended for food or chemical products.

In conclusion, Medjool bags are more than just packaging solutions; they are integral components that can enhance product safety, shelf life, and brand reputation in the competitive plastic industry. By understanding their unique properties and applications, professionals can make more informed choices that align with both operational needs and sustainability goals. Adapting these insights into your packaging strategy can lead to improved efficiency and customer satisfaction in your operations.

Key words:

Related News

CONTACT US

Email: sales8@meyabond.com

Tel: +8618911966213

No.3 Yard, ZhongHe Road, 100071,FengTai District, Beijing, China

Email: sales8@meyabond.com

Tel: +8618911966213

No.3 Yard, ZhongHe Road, 100071,FengTai District, Beijing, China